The CT1000 Concept

Revolution in handling DC and AC electric arcs

With its CT1000 contactor Series Schaltbau is introducing an innovative contactor concept to the market: power contactors in a completely new style and design, specially developed for the enhanced requirements of the railway industry. The outstanding technical feature of the new contactor series is the combination of electromagnetic and permanent-magnetic blowout in one switching device.

The successful combination of two proven technologies greatly improves the contactor’s switching functionality and reliability and makes for an innovative and economically impressive device concept.

Special requirements of railway applications

The requirements for contactors in railway technology are highly specialised and in certain areas are fundamentally different from those of other branches of industry. One of the principle differences is the use of varying supply networks from one country to the next. In Europe both direct and alternating currents of varying voltages and frequencies are used (3 kV DC; 1.5 kV DC; 15 kV 16 2/3 Hz; 25 kV 50 Hz). This has led to fundamentally changing operating conditions for power contactors used in international traffic.

Other requirements are, for example, suitability for bidirectional switching (e.g. for energy recovery) the exemption of critical current ranges and the control of high short-circuit loads.

Innovative concept

Thus the aim of the new development was to incorporate the greatly varying requirements that exist in the railway industry in a technologically and economically advantageous device concept. Schaltbau has convincingly achieved this aim with the new CT1000 contactor series, which reaps the benefits of the company’s decades of experience in designing contactors.

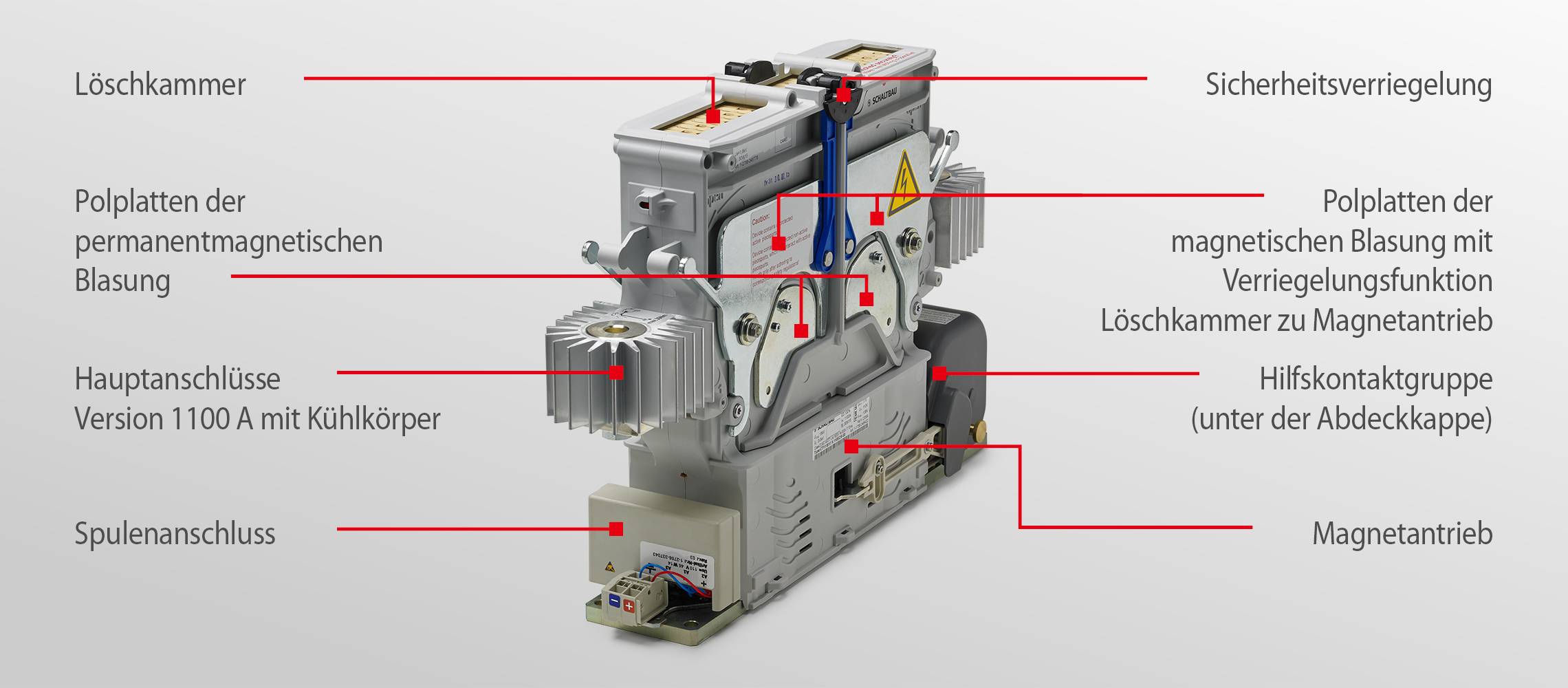

The innovative core of the new CT1000 series is the electric arc control technology: in contrast to contactor concepts purely based on electromagnetic blowout, the arcs created at the moment of switching off are ignited in powerful permanent-magnetic blowout fields.

Thus the dwell periods in the contact zones are limited to an absolute minimum. This leads to a significant reduction in arc-related burn-up when switching off. The lower degree of wear on the contacts makes it possible to greatly increase maintenance intervals.

The arcs blown out of the contact zones act as wear-free switches in the next phase: the jumping over of the arc to adjacent arc guide plates activates the blowout coils, making switching-off procedures independent of the direction of the current from that moment onwards.

In the final phase the arcs pass through an arc guide shaft, are stretched across the divergently arranged guide plates and then effectively extinguished in a ceramic chamber. The special design of the insert reduces the exiting of ionised arc exhaust gases from the arc chamber.

Double-break contacts

The double-break contact system has a symmetrical mirror-image formation. It features both high functionality and reliability, both when subjected to changing polarities and when dealing with critical currents (high voltages, low currents), which are difficult to switch.

Conclusion

The CT1000 contactor concept is flexible and can, for instance, be adapted to suit the needs of the customer with regard to the number of contacts, the design of auxiliary contacts and the connection technology. The product family, which is currently being expanded, comprises a number of various design versions catering to a wide range of uses.

Due to their technical superiority, economical benefits, compactness and versatility, the CT1000 power contactors are simply predestined for use in the railway industry.