Contactors for critical applications

Why arc quenching is so demanding for DC contactors

When Schaltbau started producing the first contactors for the railroad sector in 1929, no one could have predicted what would happen later. Today, almost 100 years later, our customers benefit from innovative, precisely fitting and certified products thanks to our many years of experience.

Whether in the railroad, energy or electromobility sectors, our contactors play a crucial role in ensuring a reliable and responsive electrical system. But why are DC contactors so important in the context of electromobility? The answer lies in their ability to seamlessly control power distribution, enabling smooth acceleration, deceleration and efficient energy utilization.

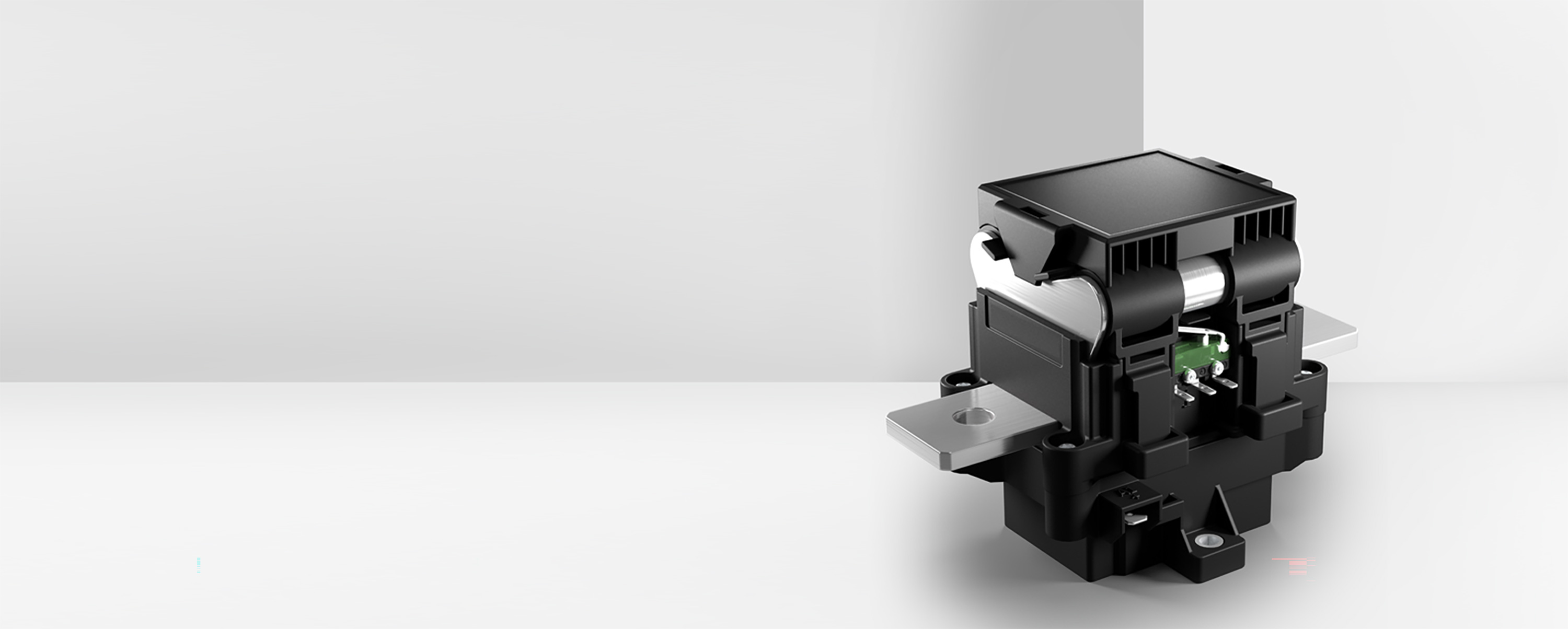

Contactors are electro-mechanical components that have become an integral part of modern life as secret helpers in the background.

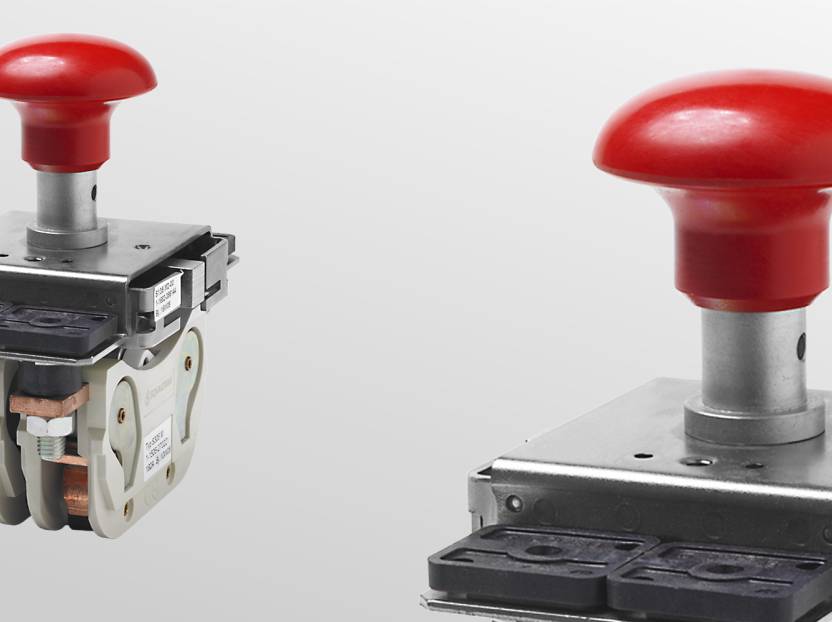

A contactor or contactor switch is an electrically or electromagnetically (in special applications also pneumatically) actuated switch for high electrical power. Contactors were developed to switch large loads remotely via control cables with a relatively small cross-section. When a control voltage is applied to the coil of the contactor, the magnetic field pulls an electrical bridge into an active state – the main contacts close. Without control voltage, springs in the contactor restore the initial state – the contact path is open again.

For example, the contactor isolates the electrical drive train galvanically from the power supply when it is switched off. If it is switched off under load, an arc is created in the contactor. In DC voltage applications, extinguishing this arc is comparatively challenging, as there is no zero crossing of the voltage.

The arc in the contactor can only be controlled if different effects work together skillfully. Only then can short arc lifetimes and therefore fast switch-off times be achieved, which are essential at this point.

The formation of this so-called switching arc has two main effects: Firstly, current continues to flow despite the contacts being open, as the plasma has a high electrical conductivity. Secondly, very high temperatures of up to 20,000 Kelvin occur, which can cause damage to the contacts of the DC contactor and surrounding system components.

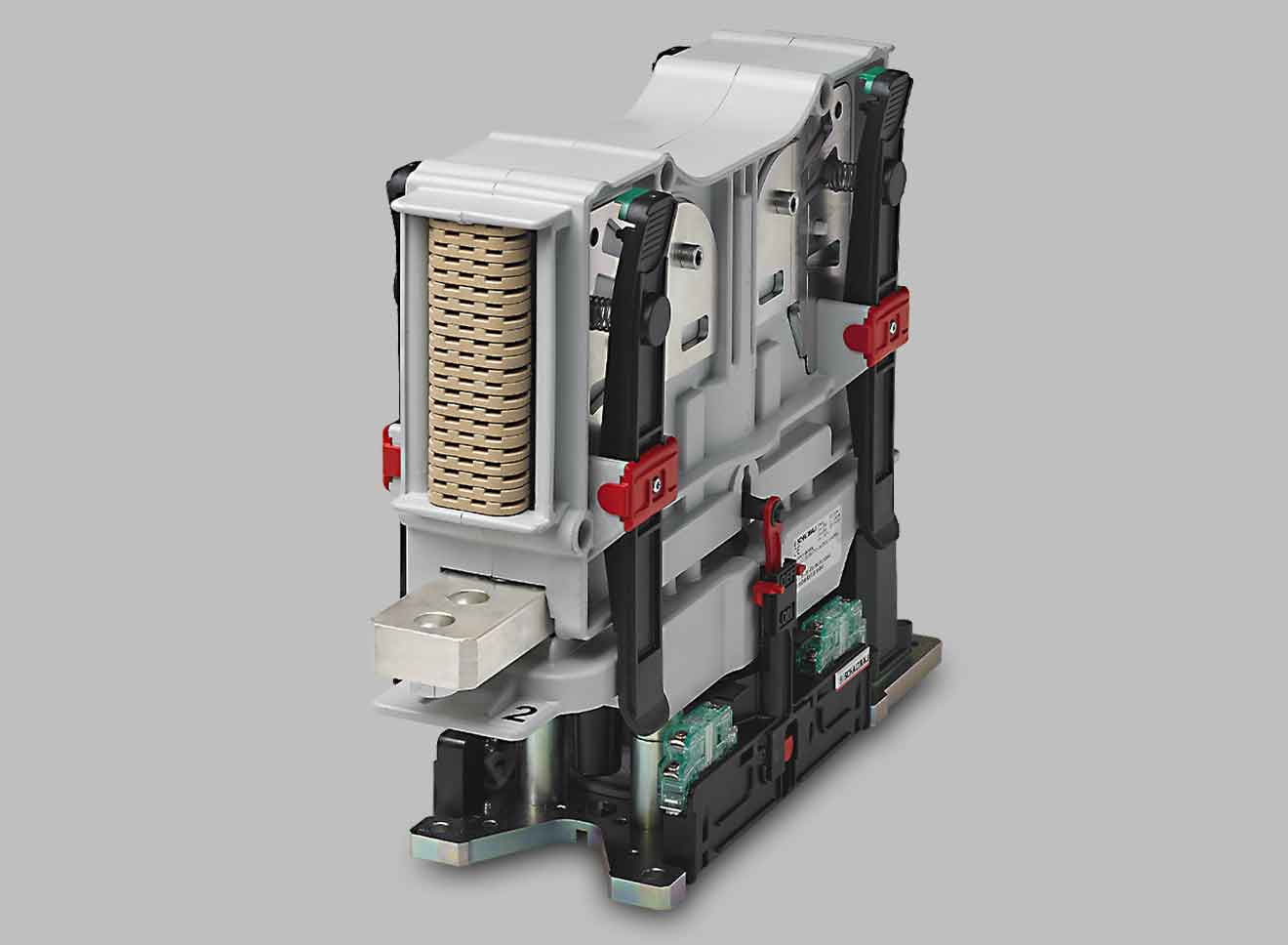

Various measures must therefore be taken in the contactor to counteract this. It is particularly important to move the arc away from the actual contact surfaces and extinguish it. This is mainly done by means of an arcing chamber, in which the arc is elongated, cooled and thus extinguished.

The arc extinguishing chamber is therefore the central functional unit in direct current or DC power contactors.