S850 - Economical redundancy for safety functions

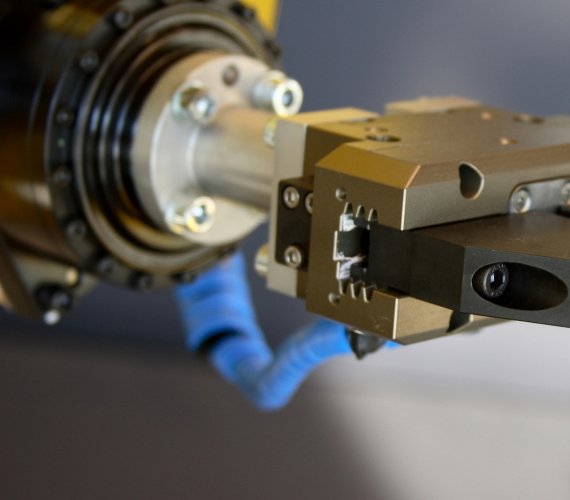

Any company that wants to sell machines or equipment in Europe – or even just the control systems for them – must adapt those systems to comply with the currently applicable machine directives. The S850 Series double NC contact switch from Schaltbau is a module for achieving standardised and economical safety solutions.

Legal basis

In recent years the directives pertaining to all applications in which people are immediately endangered (for example the operator) have become increasingly strict. The following regulations apply to control systems with safety functions:

- EN ISO 13849-1 (as replacement for EN954-1): “Safety of machines – safety-related parts of control systems”. The adaptation deadline ended December 29, 2009.

- IEC EN 61508: “Functional safety of safety-related electric/electronic/programmable electronic systems”.

The EN ISO 13849-1 directive describes the determination of safety integrity levels (SIL 1 to SIL 4), with which acceptable levels of risk of systems are estimated. The higher the risk, the higher the SIL to be achieved and the greater the cost of implementation, for example, for redundant designing of safety-related functions.

Implementing the standards

The actual technology necessary to comply with the required safety levels is not specified and for that reason various procedures are possible. In portal frame cranes for example, a second safety switch can be installed to control an end position. However, the mechanical structure may also have to be changed in order to achieve this. As an alternative, a second PLC can monitor the end position, which is considerably more expensive.

One of our customers thought up a more elegant solution: he asked us if we could build a double NC contact switch capable of switching two safety circuits at the same time. This enquiry was the spark that ignited the development of the S850.

In order to implement a double NC contact switch with positive opening operation, our designers had to develop various special solutions, for example to compensate for the varying rates of wear and burn-up of the two contact pairs – for each circuit individually and for both circuits together. The solution developed has been registered for a patent.

With the help of the S850 a great number of additional safety functions in the field of mechanical engineering can now be implemented in a standardised and economical way:

- Safe hold when protective screens are opened

- Position monitoring of moveable protective equipment

- Safe reduced speed in setup mode

- Safe emergency stop function

- Safe lifting of heavy loads

- Locking of moveable protective equipment

- Protecting of machine end positions from overruns